THT – Thru Hole Technology

THT – Thru Hole Technology

Wave Soldering

- Universal frames – wave soldering

- It is the most economical solution that can be applied, also recommended for high-mix products

- The frame has one or more adjustable bars that can be adjusted to the PCB’s size

- Open frames – wave soldering

- This solution can be applied for products which do not have to many THT components

- The base plate has tailor made pockets for the PCB and it’s SMT components and the PCB is fixed to the base plate

- Frames with top-hat – wave soldering

- The dedicated top-hat is the best choice to obtain a proper soldering

- The Top-hat has dedicated pushers with springs that holds on place the components during the wave soldering process

- The design is of the base plate and the top-hat including the pushers is always dedicated to the products

- Frames with Top-Hat – wave soldering with Titanium Insertion

- It is used in cases when the SMT components are too close to the THT components

- In these cases, a very thin edge can’t be milled out from composite material because it will either brake during the wave soldering or burn out too fast, in this cases the Titanium is recommended because it will not be affected by the heart and the very thin edge is possible to obtain, about 0,4 – 0,5mm

- The top-hat also has dedicated pushers to hold on place the components

Selective Soldering

- Universal Frames – Selective Soldering

- It is the most economical solution that can be applied, also recommended for high-mix products

- The frame has one or more adjustable bars that can be adjusted to the PCB’s size

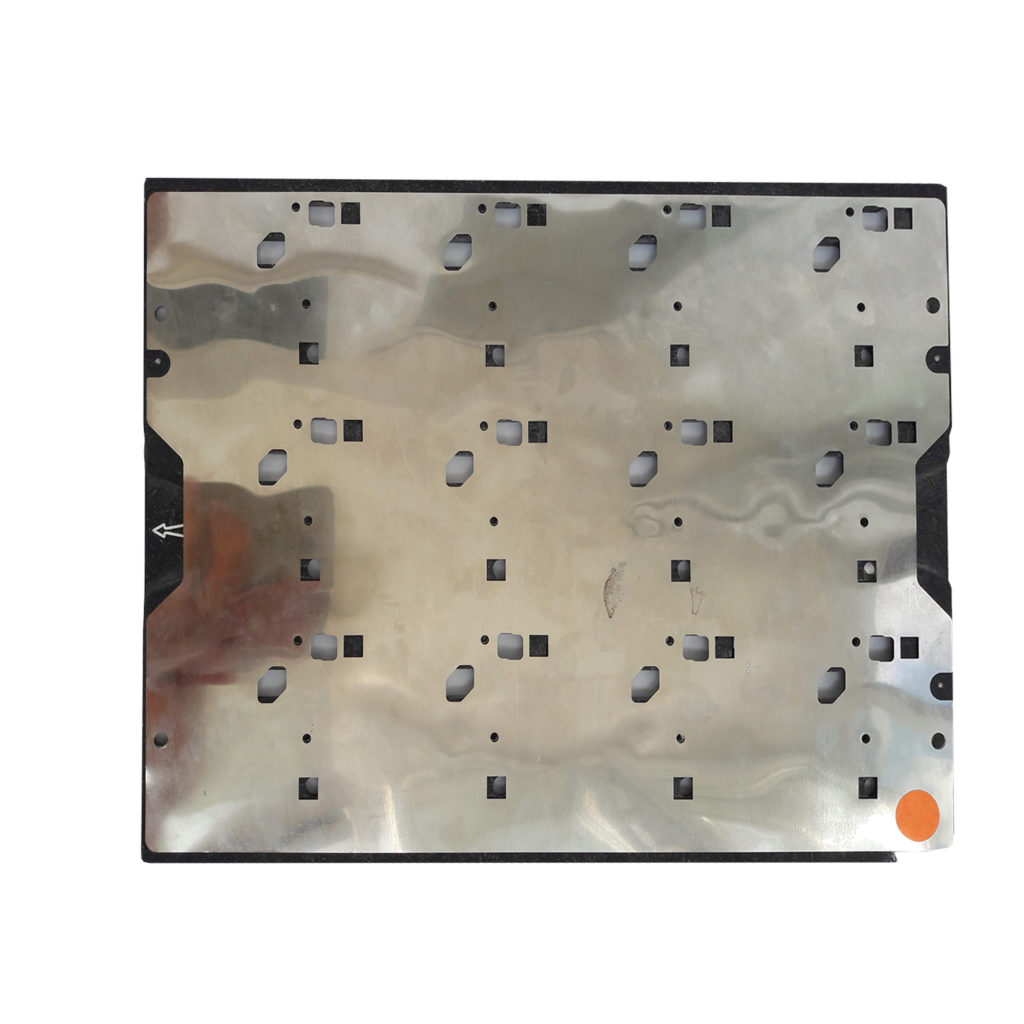

- Open Frames – Selective Soldering

- This solution can be applied for products which do not have to many THT components

- The base plate has tailor made pockets for the PCB and it’s SMT components and the PCB is fixed to the base plate

- Frames with Top-Hat – Selective Soldering

- The dedicated top-hat is the best choice to obtain a proper soldering

- The Top-hat has dedicated pushers with springs that holds on place the components during the wave soldering process

- The design is of the base plate and the top-hat including the pushers is always dedicated to the products

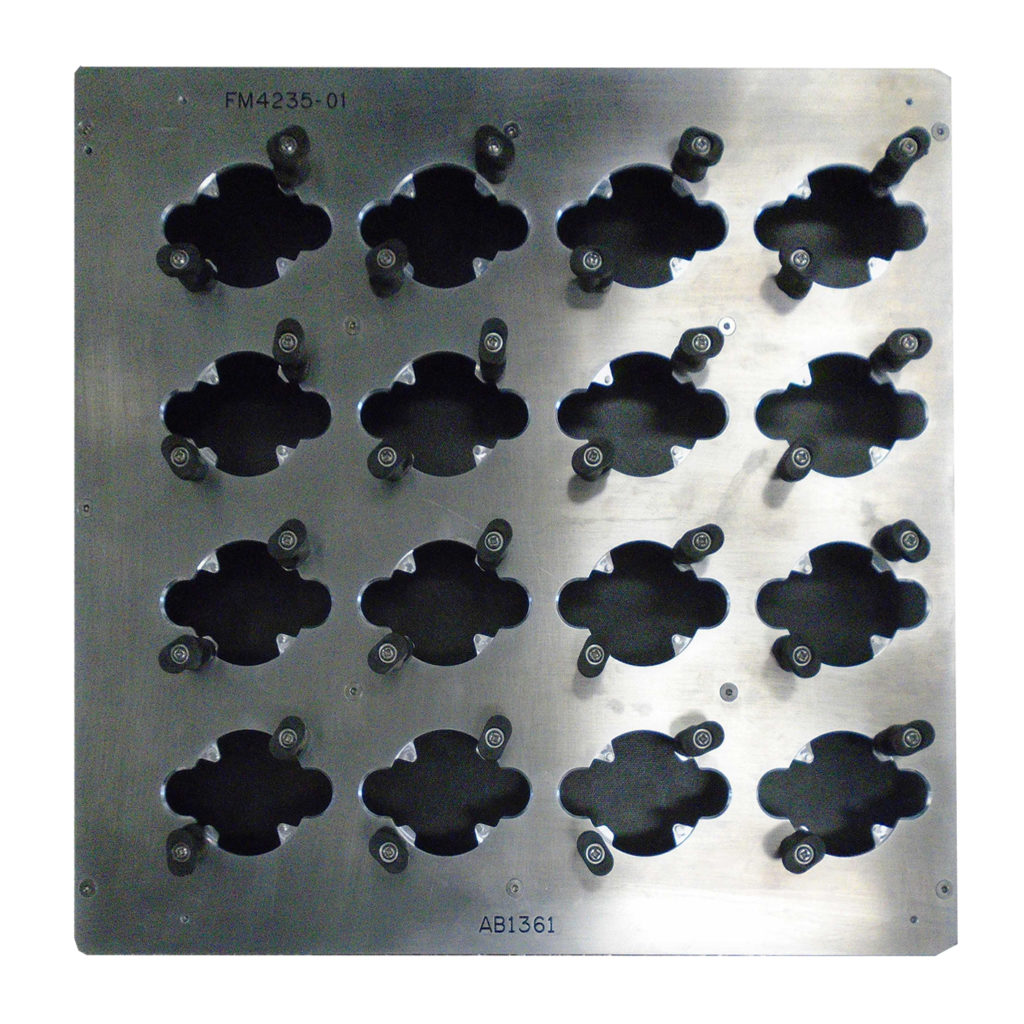

- Nozzles and Nozzle plates for Selectwave

- The nozzles are tailor made according to the customer’s specifications